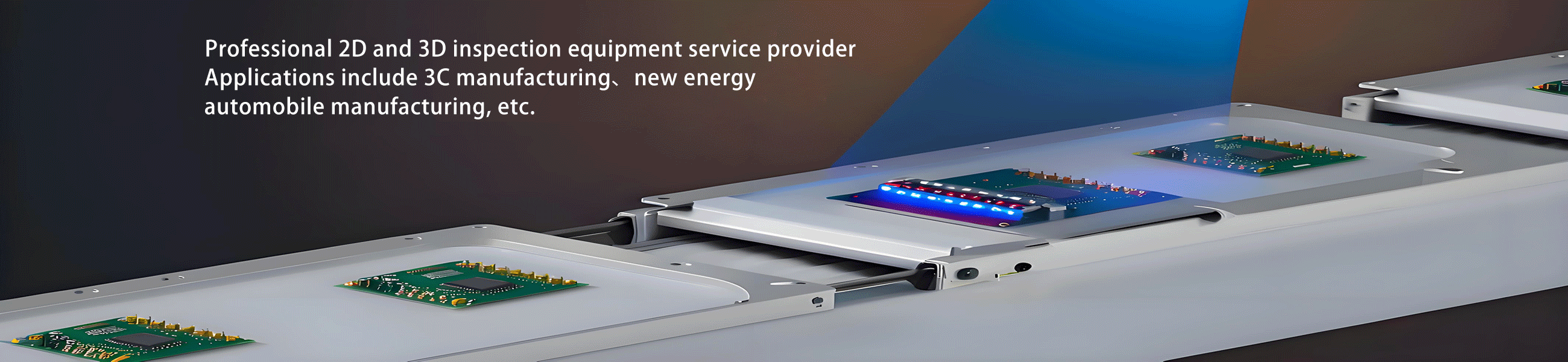

Leading active dual-stripe light technology

· Using active dual-stripe light technology, the light projector projects a series of composite stripe lights containing specific spatial phase encoding onto the surface of the object

· Using active dual-stripe light technology, the light projector projects a series of composite stripe lights containing specific spatial phase encoding onto the surface of the object

· The COMS sensor at the receiving end receives the phase of the moving stripe light wave multiple times through the phase shift method

· The COMS sensor at the receiving end simultaneously captures the changes in the stripe light and then decodes the resulting photos

· After decoding, the target object can be illuminated with stripe light to measure the height difference by triangulation. The stripe-shaped light irradiated by the projection lens is diffused on the surface of the target object

· After decoding, the target object can be illuminated with stripe light to measure the height difference by triangulation. The stripe-shaped light irradiated by the projection lens is diffused on the surface of the target object

· If the reflected light is observed from other angles (receiving end lens), it can be seen that the original stripe-shaped light is emitted due to the concave and convex shape of the target object

· These lights are imaged by the COMS sensor and calculated (triangulation method), thereby measuring the height and position of each point

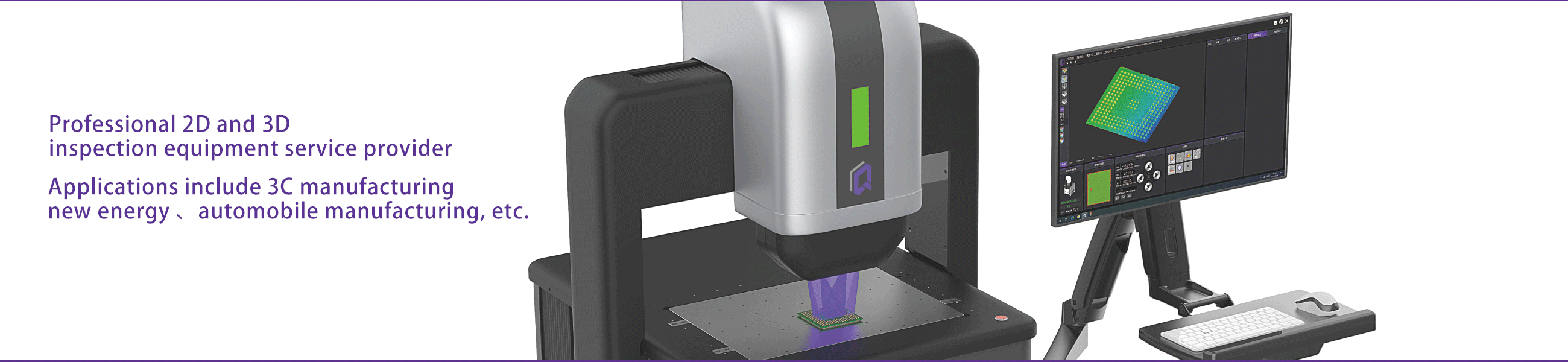

Micoron-level 3D detection

· Using large-size and high-precision COMS, low-noise data can be obtained. Because each pixel obtains RGB data, it can also observe with excellent color reproducibility and vividness

· Using large-size and high-precision COMS, low-noise data can be obtained. Because each pixel obtains RGB data, it can also observe with excellent color reproducibility and vividness

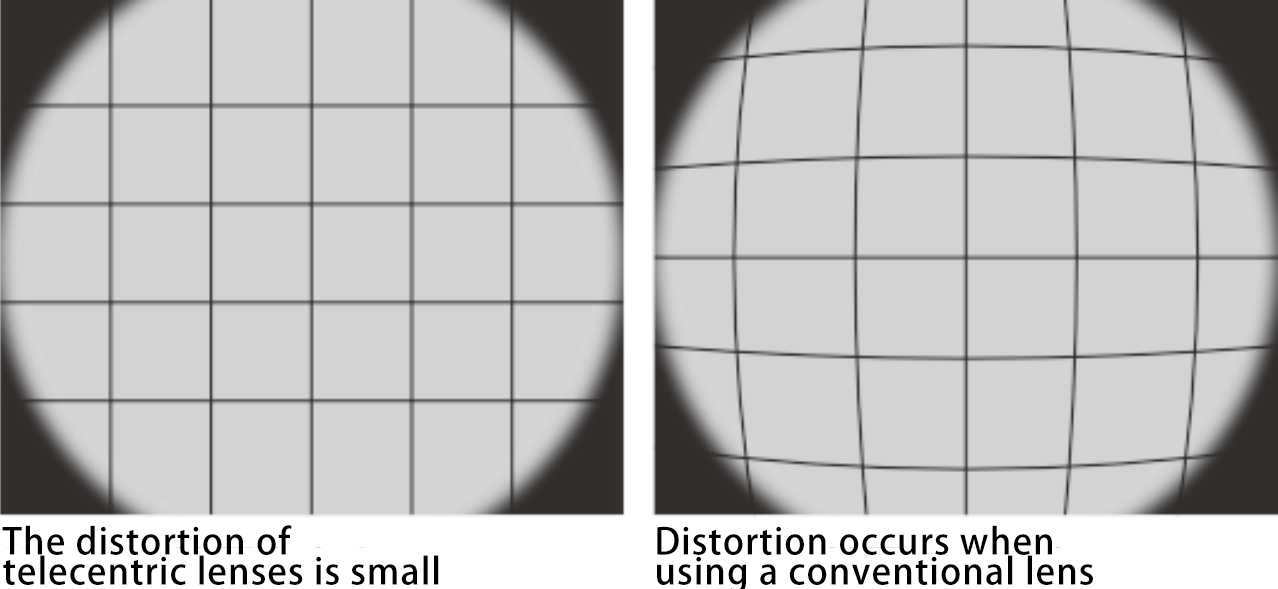

· With a high-precision telecentric lens, the effect of distortion can be reduced, and images with no blind spots can be captured at "actual size", thus achieving accurate shooting

· Using circular projection in two directions, images with no blind spots can be captured without being affected by directionalit

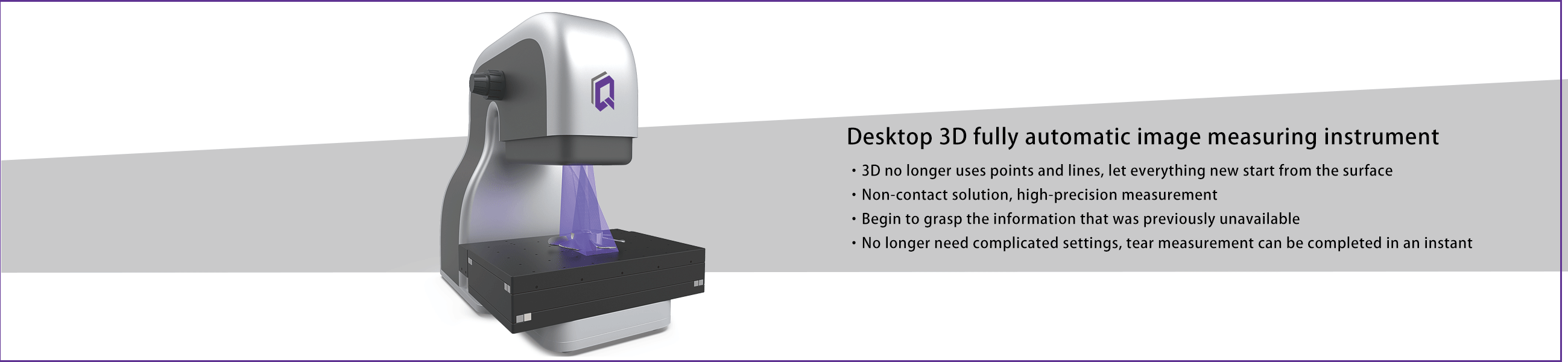

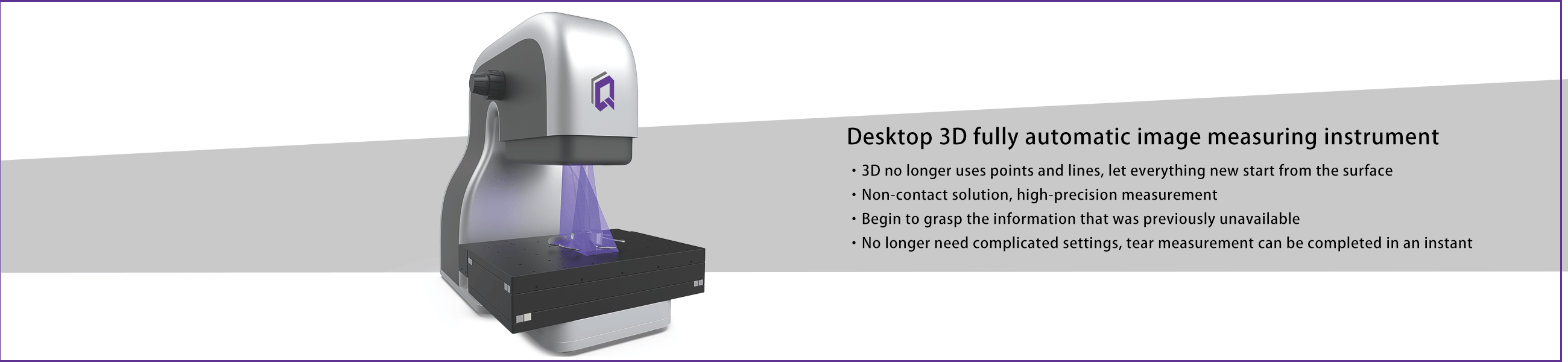

Inspection in as fast as one second,no more contact inspection

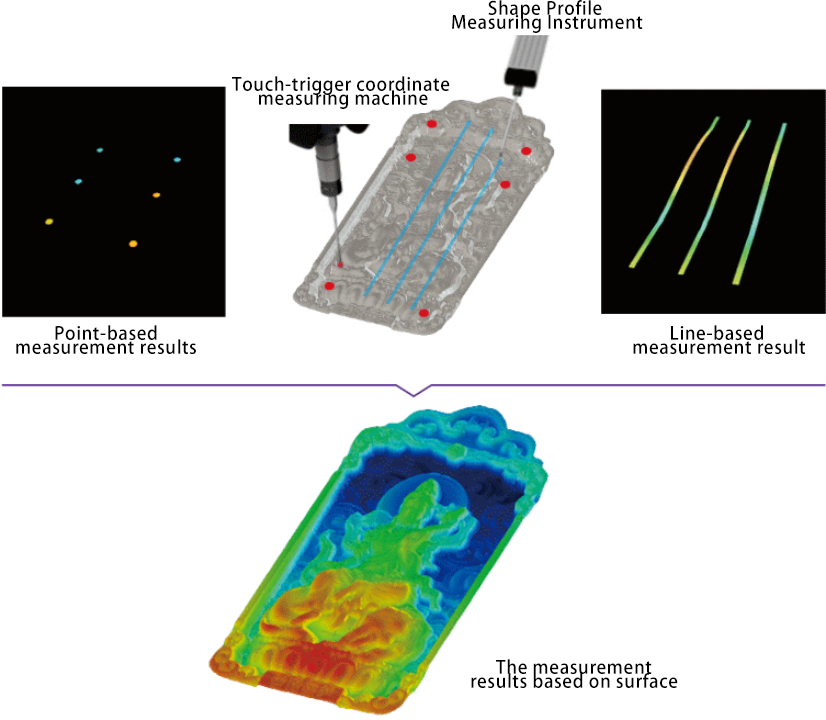

If you use traditional measuring instruments (point, line, contact measurement) for measurement, some shapes are difficult to measure accurately, but using the gantry-type 3D fully automatic image measuring instrument series, it is no longer measured by traditional measurement methods. The equipment uses a surface scanning method, which can scan the target more accurately and efficiently, and can largely avoid problems such as shape errors

Gantry machine Product technical parameters

| Shooting efficiency (Maximum) | ≤10 times/sec(@2M); 3 times/sec(@8.1M) |

| Observation range (single field of view) | 1024mm2 |

| point cloud range | 7910 pcs/mm;8.1 million per shot |

| Standard working distance | 120mm |

| Z-axis measurement range | ±3mm |

| Z-axis adjustment range | ±80mm |

| Z-axis reduplication accuracy (1g) | 0.001mm |

| Platform mobile shooting range (Maximum) | 300mm x 400mm |

| Platform movement accuracy | ±0.002mm |

| Platform grating ruler resolution | 0.5um |

| Platform movingt speed (Maximum) | 40mm/sec |

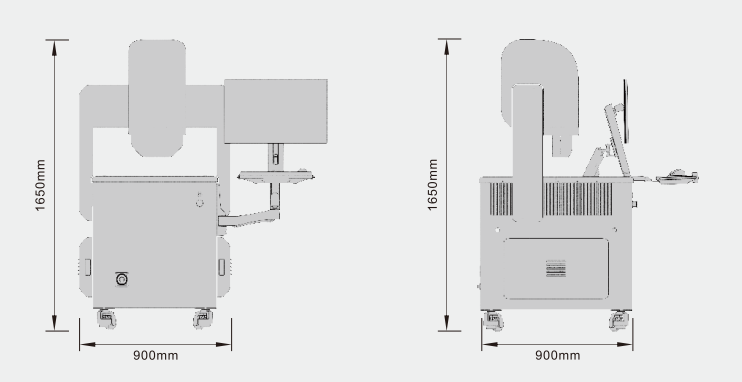

| Device size | 900mm x 900mm x 1650mm |

| Equipment weight | 500KG |

| Input Voltage | 100-240VAC,50/60HZ,10A |

Workstation technical parameters

| Workstation model | Think

Station

-

P360

Tower | |

| CPU | INTEL i7- 12700 | |

| Memory specifications | 32GB DDR5-4800MHZ | |

| Graphics | nVidia RTX3060 12GB 3DP+HDMI | |

| Hard Disk #1 | 512GB SSD M.2 | |

| Hard Disk #2 | 1TB HD7200RPM 3.5" | |

| Data interface | Front data interface | 2*USB3.2 Gen2 Type-A |

| 1*USB3.2 Gen2 Type-C | ||

| Read data interface | 2*USB3.2 Gen1 Type-A | |

| 2*USB3.2 Gen2 Type-A | ||

| Network Card | RTL8168H PCIE 1000M FH | |

| Display and interface | 2K 2560 X1440 : DP+HDMI2.1 | |

| Case size volume | 315.4*376*170mm;17L | |