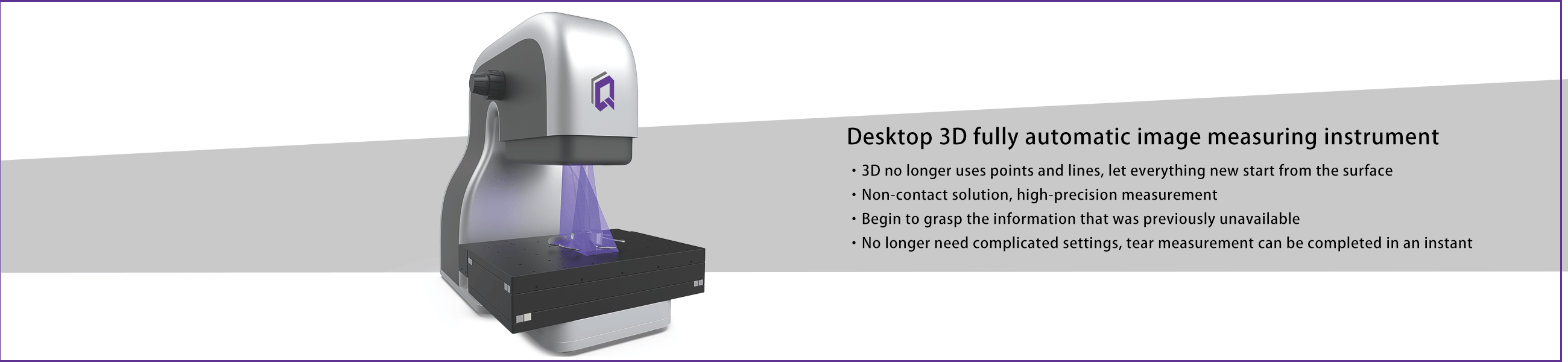

Leading active dual-stripe light technology

· Active stripe light technology, the light projector projects a composite stripe light containing a specific spatial phase code onto the surface of the object

· The COMS sensor at the receiving end receives the phase of the moving stripe light wave multiple times through the phase shift method

· The COMS sensor at the receiving end simultaneously captures the changes in the stripe light and then decodes the resulting photos

· The stripe-shaped light irradiated by the projection lens is diffusely reflected on the surface of the target. If you observe the reflected light from directly above (light-receiving lens), you can see that the original stripe-shaped light is bent due to the concave and convex shape of the target

· The stripe-shaped light irradiated by the projection lens is diffusely reflected on the surface of the target. If you observe the reflected light from directly above (light-receiving lens), you can see that the original stripe-shaped light is bent due to the concave and convex shape of the target

· These lights are imaged by the COMS sensor and calculated (triangulation distance measurement method), thereby measuring the height and position of each point

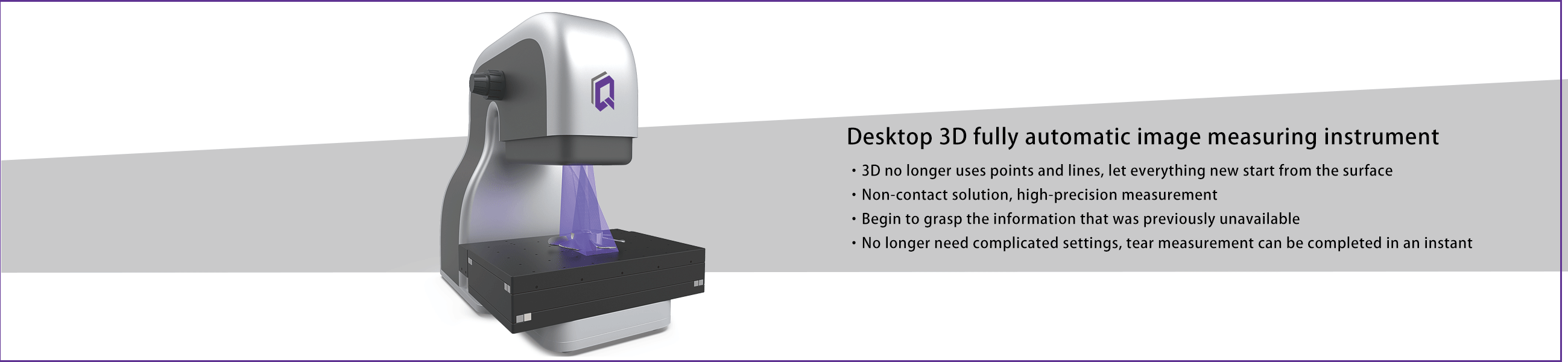

No need for pre-arrangement,advance preparation

In order to avoid movement when setting the sample, the contact measuring instrument needs to be fixed with a fixture, or leveled, or select a needle, probe, etc., and various advance preparations are made. If you use the Kunting series 3D image measuring instrument, you only need to place the sample on the stage and click the measurement button to complete the measurement, which is very easy.

In order to avoid movement when setting the sample, the contact measuring instrument needs to be fixed with a fixture, or leveled, or select a needle, probe, etc., and various advance preparations are made. If you use the Kunting series 3D image measuring instrument, you only need to place the sample on the stage and click the measurement button to complete the measurement, which is very easy.

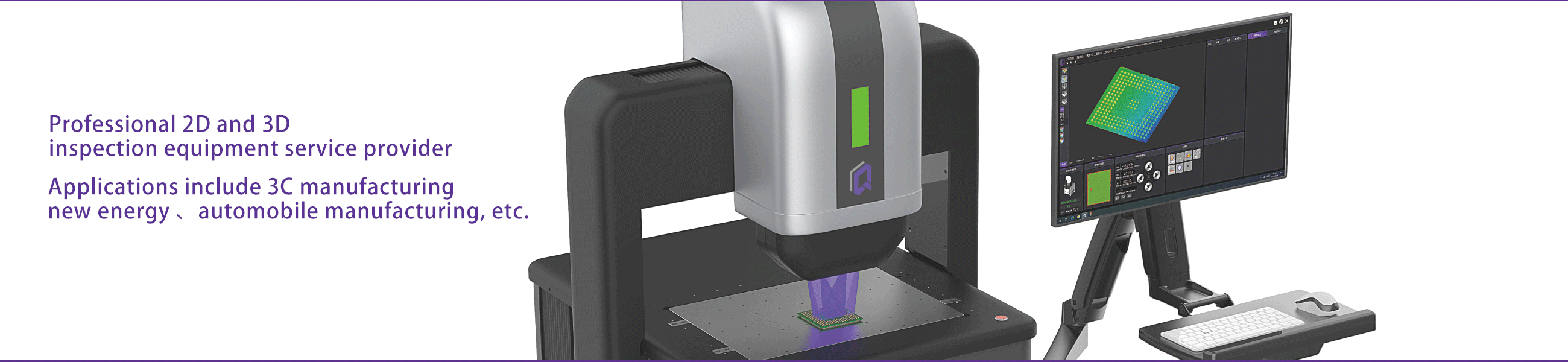

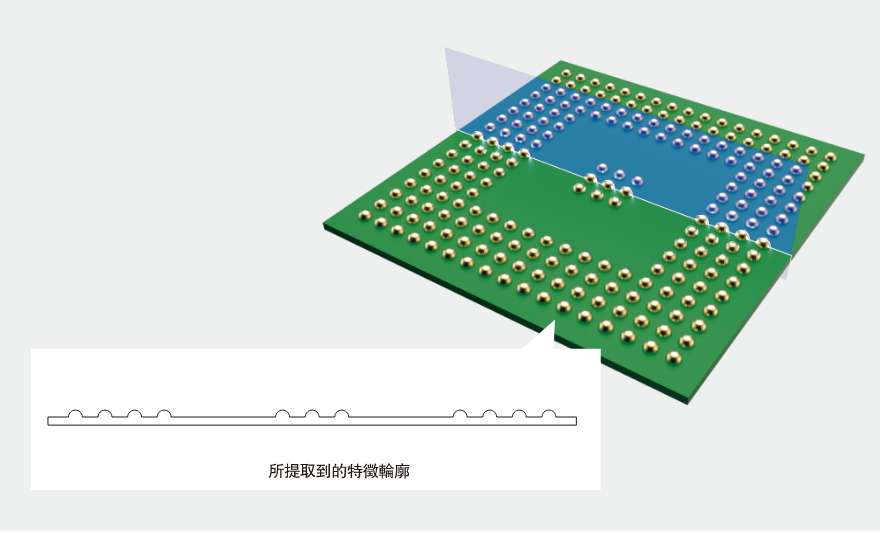

Fastest one second detection,no more contact detection

If you use traditional measuring instruments (point, line, contact measurement) for measurement, some shapes are difficult to measure accurately, but using the desktop 3D fully automatic image measuring instrument series, no longer use traditional measurement methods for measurement, the equipment uses a surface scanning method, so as to scan the target more accurately and efficiently, which can largely avoid the shape

The Kunting series 3D image measuring instrument has achieved a measurement speed of the fastest 1 second through the improvement of measurement algorithms and hardware. This has greatly increased the number of samples, shortened working time, and improved the quality and efficiency of measurement work such as trial product analysis and process inspection.

The Kunting series 3D image measuring instrument has achieved a measurement speed of the fastest 1 second through the improvement of measurement algorithms and hardware. This has greatly increased the number of samples, shortened working time, and improved the quality and efficiency of measurement work such as trial product analysis and process inspection.

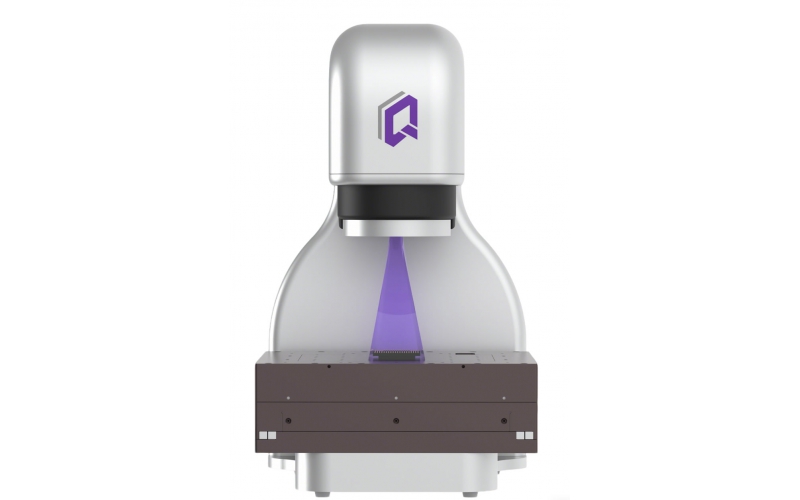

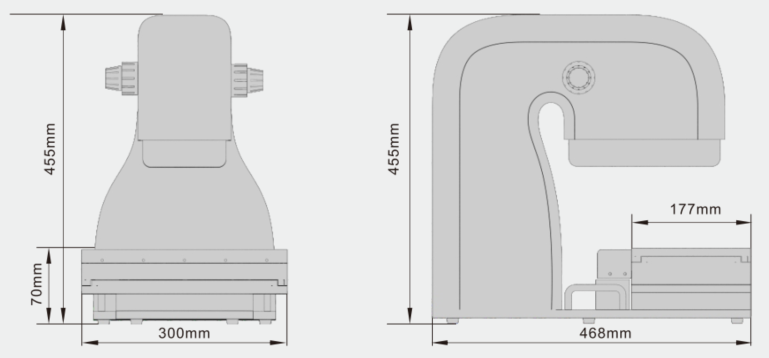

Little Dolphin Product technical parameters

| Shooting efficiency (Maximum) | ≤8.6 times/sec(@1.3M); 2.5 times/sec(@5.1M) |

| Observation range (single field of view) | 1200mm2 |

| point cloud quantity | 4250 pcs/mm;5.1 million per shot |

| Standard working distance | 100mm |

| Z-axis measurement range | ±5mm |

| Z-axis adjustment range | ±25mm |

| Z-axis reduplication accuracy (1g) | 0.001mm |

| Platform mobile shooting range (Maximum) | 160mm x 100mm |

| Platform movement accuracy | ±0.005mm |

| Platform movement speed (Maximum) | 35mm/sec |

| Device size | 468mm x 300mm x 455mm |

| Equipment weight | 25KG |

| Input Voltage | 100-240VAC,50/60HZ,3.8A |

Workstation techbical parameters

| Workstation model | Think Station - P360 Tiny | |

| CPU | INTEL i7- 12700 | |

| Memory Specifications | 16GB DDR5-4800MHZ | |

| Graphics | intel UHD 730/770 integrated graphics | |

| Hardddisk | 512GB SSD M.2 | |

| Data interface | Front data interface | 2*USB3.2 Gen2 Type-A |

| 1*USB3.2 Gen2 Type-C | ||

| Rear data interface | 2*USB3.2 Gen1 Type-A | |

| 2*USB3.2 Gen2 Type-A | ||

| Network Card | RTL8125BGS 2.5G(双网口) | |

| Wireless network card | RTL8852BE 2x2ax+BT WW | |

| Display and interface | 2K 2560 X1440 : DP+HDMI2.1 | |

| Chassis size volume | 179*182.9*37mm

;1L | |